CNC horizontal QK1313 automatic Pipe Threading Lathe Machine

The CNC pipe threading machine is developed for the oil field pipe thread turning and it is suitable for all types of pipe threads turning. The machine also can be used as general CNC lathes to machining complex shapes,like shaft sleeve, disc-type parts.

Pipe Threading CNC Lathe QK1313 features:

| Double chuck | Big spindle |

| Servo main motor | Taiwan ball screw |

| High efficiency | -- |

Characters

1. We set up TRB (tapered rolling bearings) on this lathe to increase the rigidity of the spindle.

2. The spindle bore is very large and set up double chucks both front and back and you can choose electric chucks as you like.

3. The surface of the slide rail of the bed is treated by the super audio quench, which can be

endurable and wear-resisting.

4. The slide rail f saddle is treated by wear-resisting layer coated, to avoid the crawling.

5. There are two types of speed change: Manual and step less.

6. Set up self lubrication system, and easy to maintain.

Specification

| Lathe specifications | Specifications |

Technical specifications | Maximum diameter of lathe bed (mm) | φ610 |

Maximum tactical diameter of sliding plate(mm) | φ350 | |

Maximum work-piece length (mm) | 1000 | |

Main drive | Form | Main motor servo stepless |

Rank of spindle speed | No grade | |

Range of spindle speed(r/min) | 50-850 rpm | |

Terminal structure | C11 | |

Hole diameter of spindle (mm) | Φ140 | |

The maximum diameter of the tube | 135mm | |

Power of main motor (KW) | 11KW(servo) | |

Feeding system | Maximum route of knife rest (mm) | X:310 Z:1150 |

Speed of quick-travel (mm/min) | X:4000 Z:5000 | |

Resetting accuracy | X:0.012 Z:0.016 | |

Precision of work piece | IT6-IT7 | |

Surface roughness | Ra1.6 | |

Tailstock | Sleeve diameter of tailstock (mm) | Φ75 |

Sleeve trip of tailstock (mm) | 150 | |

Cone hole taper tailstock's sleeve | MT5 | |

Knife rest | Standard configuration | Four-station vertical electrical knife rest |

Alternative configuration | Horizontal Six-station electrical knife rest | |

Resetting accuracy (mm) | 0.01 | |

Length of section of knife handle (mm) | 30×30 | |

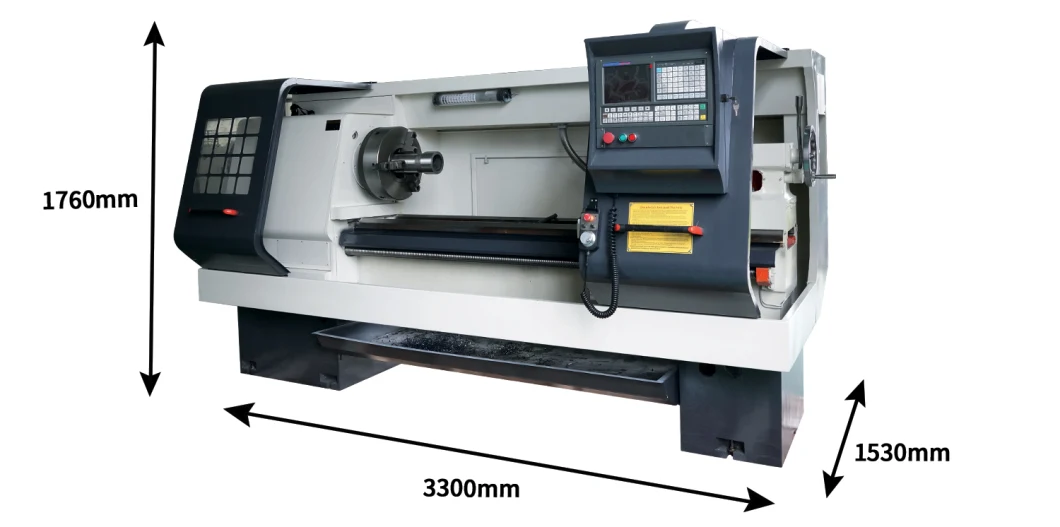

Machine size weight | Length*width*height | 3500×1755×1900 |

Net weight (Kg) | 3500Kg |

Standard configuration

| CNC System:GSK-980TDc | 3 jaw manual double chuck |

| 4 station tool | Manual tailstock |

Lighting system | Cooling system |

Automatic lubrication system | 3 phase 380v 50Hz |

Optional configuration

Siemens system /Fanuc system |

Hydraulic chuck/ pneumatic chuck |

6-piece electric tool post/8- piece electric tool post |

SERVICE

you satisfied is our business!

1. The first batch of supplier joined Alibaba Trade Assurance.

Amount up to the top of Machinery Industry. Zero-risk Purchase service.

2. Over 400 clients from more than 100 countries could tell you we are your reliable

partner.

3. Professional in cnc machine.

Our price could beat any competitors in China market.

4. We supply professional solution based on your own process one by one.

5. Customer-made configurations available. Provide you more choices.

6. 7*24 hours before and after sale service.